In the world of Smart Farming, precision control is at the heart of enhancing quality and reducing risks. A cacao fermentation system has been developed using IoT technology, designed to suit real environmental conditions, with data seamlessly transmitted to the Smart Farming Cloud platform.

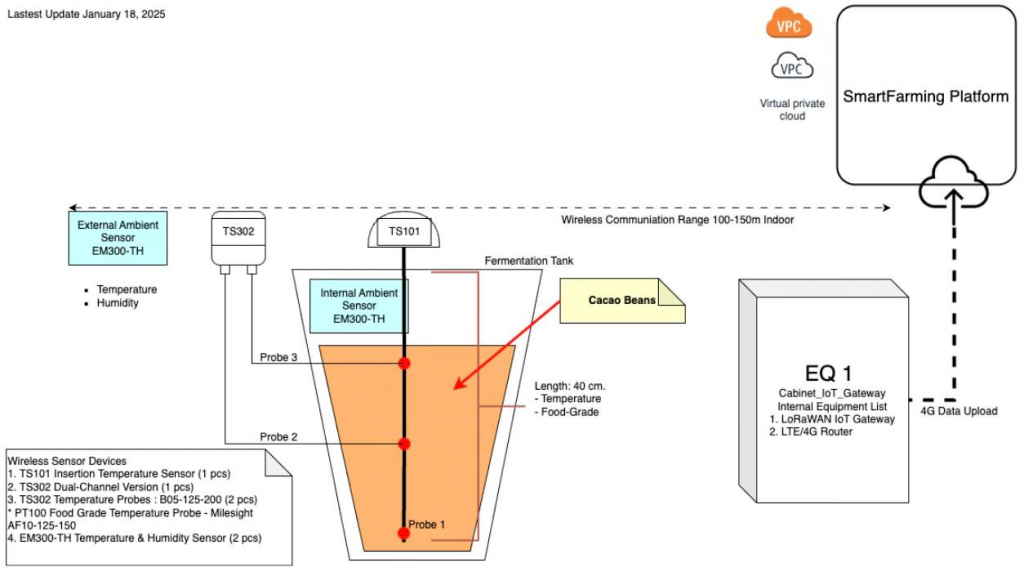

Installed IoT System Structure

Device Installation Points:

- A modified wooden fermentation box equipped with three levels of food-grade temperature probes.

- An EM300-TH sensor is used to measure both internal and external temperature and humidity.

- Wireless connectivity via LoRaWAN to a gateway, which transmits data through a 4G network to the cloud platform.

Key Devices

- TS101: Insertion sensor for measuring temperature at the bottom of the fermentation pile.

- TS302: Dual-channel probe for multi-level temperature measurement in the middle and upper parts of the pile.

- EM300-TH: Sensor for monitoring environmental conditions and inside the fermentation tank.

- LoRa Gateway + LTE Router: Control cabinet unit (EQ1).

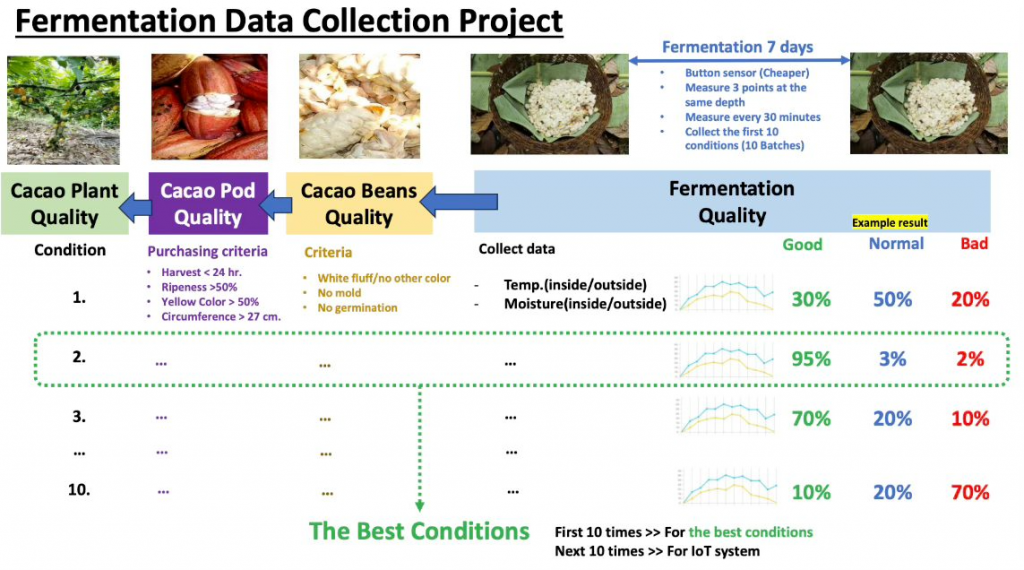

Data Collection Objective: To develop a standardized “fermentation formula.”

Data Conditions:

- Monitor every 30 minutes (collect and sample data within 5 minutes) at three depth levels.

- Collect data for at least 10 fermentation cycles to determine the best conditions.

- Analyze data using graphical representations of both temperature and humidity (inside and outside).

The dashboard displays real-time tracking data from sensor TS101 (Channel 0), which is installed inside the cacao fermentation tank. Key observations are as follows:

Temperature

- Maximum recorded value: ~40.3°C on April 26, 2025

- Fluctuations observed throughout the period from April 27 to May 6

- Trend: A noticeable peak occurred between late April and early May, indicating an intensive fermentation phase. The temperature declined after May 2.

- Insight: Temperature rose and fell in line with the fermentation cycle and pile turning activities. It is likely that material was added or removed, or aeration was performed during these periods.

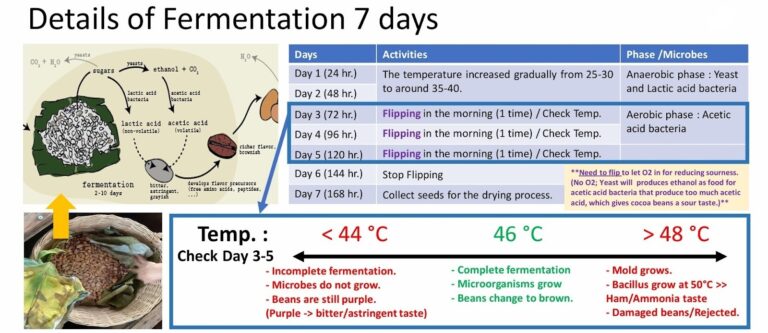

Details of the 7-Day Cacao Bean Fermentation Process: The process spans 7 days, with a key focus on temperature control during days 3 to 5 to ensure optimal and complete fermentation.

Recommendations Based on the Data:

A temperature range of 35–40°C is suitable for effective fermentation, indicating that the process is likely to be successful.

Conditions for Optimal Cacao Fermentation:

- Select white cacao beans free from mold.

- Harvest pods within 24 hours and ensure a ripeness level with more than 50% yellowing.

- Pod circumference should be greater than 27 cm.

Results from the System

From the first 10 data sets:

- 95% of fermentation batches achieved high quality when using precise sensors and controlled conditions.

- Reduced waste from failed fermentation batches (only 2% bad batches).

- Potential to expand the system with AI to predict future fermentation cycles.

Next Steps: From Local Farms to an Export Model

With this model, CABMA believes that smallholder farmers can:

- Implement a traceability system.

- Establish export-quality standards.

- Connect with Blockchain or ESG tracking systems in the future.

Join Us in Building the Smart Fermentation System

Cacao fermentation is no longer just an art — it is data-driven quality guidance.

#SmartFarming #IoT #CacaoInnovation #CABMAPlatform

References:

[1] Facebook: 🌱🚀 Continuing Innovation in Smart Farming! 🚀🌱

[2] de Melo Pereira et al. (2022). Cocoa Bean Fermentation. https://www.mdpi.com/2311-5637/8/7/331